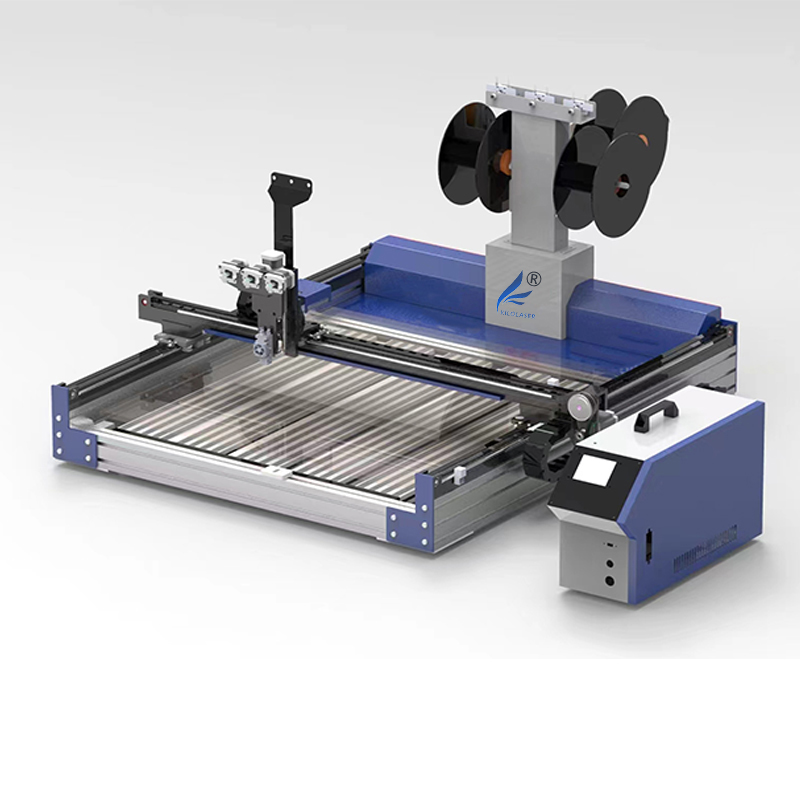

| Name: | Luminous Channel Letters Sign 3D Printer for Outdoor and Indoor |

|---|---|

| Machine Model: | C80,S80,S120,SP80,SP120,SPro80 |

| Working Table: | 80x80/120x120cm |

| Effective Printing Area: | 78x78/118x118cm |

| Power Supply Voltage: | 110V/220V, 50-60Hz, |

| Power Requirements: | 720W |

| Extruder: | 3 Color Extruder |

| Forming head size(Optional): | 0.6mm |

| Layer Resolution: | 100μm |

| speed: | 50mm-100mm/s |

| Printing Hight: | 65mm,90mm |

| Software: | Youtonda Original 3D Channel Printing Software |

| Supported Systems: | Windows 7 and above (64-bit) |

| Weight: | 95kg 105kgs 125kgs |

| Inquiry |

Product Description

Luminous Channel Letters Sign 3D Printer for Outdoor and Indoor

Technique Parameter:

| Industrial 3D Channel Letter Printer | ||||||

| Seris | YTD-C | YTD-S | YTD-SP | YTD-SPro | ||

| Model | C80 | S80 | S120 | SP80 | SP120 | SPro80 |

| Printing Technology | FDM | |||||

| Printing Software | INC (2D to 3D Slicing Software) | |||||

| Print Size(LxWxH) mm | 800x800x65 | 800x800x100 | 1200x1200x100 | 800x800x100 | 1200x1200x100 | 800x800x100 |

| Extruder type | Nozzle Diameter 0.6mm (Optional),Automatic color change | |||||

| Print Bed | Heated Temperature 50-80°C, removable, and with dynamic automatic leveling | |||||

| Connectivity | USB, Wi-Fi, or SD card | |||||

| Layer Resolution | 100μm | |||||

| Supported File Formats | CDR, DXF | |||||

| Supported Computer Operating Systems | Windows(7+),64Bit | |||||

| Printing Speed | 45mm-60mm/s | |||||

| Filament Compatibility | PLA,PLA Composite,ABS,PETG,PETG Composite | |||||

| Power Requirement | AC 110/220V±10%,50/60Hz,720W | |||||

| Safety Features | Thermal cutoffs, overcurrent protection | |||||

| Configuration | 1Nozzle ,2Extruder | 1Nozzle ,3Extruder | 1Nozzle ,3Extruder | 1Nozzle ,3Extruder | 1Nozzle ,3Extruder | 1Nozzle ,3Extruder |

| With Curing Platform | / | / | / | Yes | Yes | / |

| With Curing Box | / | / | / | / | / | Yes |

| Machine Size(mm) | 1360*1340*870 | 1800*1700*870 | 1390*1340*870 | 1800*1700*870 | 1390*1340*870 | 1390*1300*1510 |

| Machine Weight (kgs) | 95 | 95 | 105 | 95 | 105 | 125 |

| Item | Descrption | Model | Specifications | ||

| 1 | 3D Printing Filaments | YTD-TF (Translucent Filaments 8 Color) | Material Type: | PC+PETG Composite Material | |

| Diameter: | 1.75mm | ||||

| Translucent Filaments Color: | White,Red,Orange,Yellow,Green ,Light Blue,Rose Pink | ||||

| Non Translucent Filaments Color: | White,Black,Grey,Light Grey | ||||

| Weight | 1kg per roll,3kgs per roll (optional) | ||||

| 2 | YTD-NTF (Non Translucent Filaments 4 Color) | Packaging Type | Spool | ||

| Package Weight | 1.3kgs per roll /3.4kgs per roll | ||||

| Thermal resistance temperature | -40-65°C | ||||

| Tensile Strength | 11-16N | ||||

| Melt Index Rate | 6.7-13.4 mg/s | ||||

| Adaptable Environment | Suitable for both Indoor and Outdoor Use | ||||

| Special Features: | High hardness,high flexibility, heat resistance,UV resistance,Good flowability, resistant to foaming, | ||||

| 3 | One Layer Curing Machine | YTD-OLCM | Voltage Requirement | AC220V/50/60Hz | |

| Glass Platform Size: | 868MM*820MM | ||||

| Load Current: | 400W/900W | ||||

| Two Layer Curing Machine | YTD-TLCM | Operating Time: | White Super Glue 90 minutes Color Glue 120minutes | ||

| Layer QTY | 1Layer /2Layer optional | ||||

| Scope of Application: | Super Letters/3D Luminous Letters | ||||

| 4 | Glass Platform Glue | 1000g/Bottle | Advantages Features: 1,Adopt Premium raw materials ,Strong adhesion, 2,Easy to Clean, Water-washable,Simply Wipe with a Damp Cloth 3,High heat resistance,The bottom of the 3D Letter not warp 4,Smooth Application, Fast-Drying and Secure Adhesion | ||

| Use Instructions : Step 1,shake the glue evenly Step 2, use a cloth to dab some glue directly onto the glass platform. Only apply glue to areas that haven't been coated yet; there's no need for a second coat. Step 3,The glue initially appears white when applied, but once it becomes transparent, you can start printing | |||||

| 5 | acrylic Liquid Glue | White, 25KG/PKG Transparate 25KG/PKG Black turns white 25KG/PKG | 1,Easy to operate, DIY illuminated letter panels 2,Time-saving, labor-saving, long storage life, 3,resistant to yellowing, minimal odor, equipment protection, 4,excellent light transmission, equal transparency on both sides after curing, 5,demolding without water | ||

| Use Instructions : Step 1,Place the letter shell on the curing machine platform, Step 2,Pour the glue into the Letter Shell Step 3,cover the curing machine, After 90 minutes, the curing process is complete | |||||

| 6 | Color toning pigments for Liquid Acrylic Glue | 800g/Bottle | 6 Color : Red,Pink,Green ,Apple Gree ,Rose Red,Yellow | ||

Advantages:

1. Automatically generate lapel or track letters without the need for third-party software, supporting the one-click generation of straight, mini, or irregular edges.

2. Independently set the height of letter frames and cores to achieve easy color matching and pre-sealing for mini letters.

3,Edit the starting point path for printing as needed, minimizing jumps and reducing streaks.

4,Automatically replenish material in case of shortage during printing, adjusting the distance based on the travel distance without manual intervention.

5,Auto-layout feature for importing and generating entire sets of letters with unchanged installation dimensions.

6,Customize bottom plates with water holes, wire holes, gourd holes, etc. Hole positions are at the same height as the bottom plate but not aligned with the edges.

7,Customize patterns on panels freely in two or three dimensions, breaking free from software constraints for more personalized designs.

8,Alter the shape of the edge band according to customer requirements for a more differentiated product.

9,Platform auto-correction with glass database memory.

10,Automatic segmentation of large letters, enabling non-closed printing for time and material savings, and easy assembly.

11,Addition of V-shaped grooves for neon lights, securely holding silicone strips without the need for glue, reducing adhesive costs.

12,File-saving functionality for simplified after-sales service; can also print 3D neon lights in a single run.

13,Independent temperature adjustment for extruders 1 and 2.

14,Scheduled automatic startup to reduce wait time.

15,Various transmission methods, including remote WIFI and wired connections, with mobile app integration for machine control.

16,Automatic braking when printing rounded or right angles to optimize printing results.

17,Automatic color layer conversion between positive and negative prints, reducing the likelihood of file errors.

Application:

Widly used in produce the Panel Integral Letters, Abyss Letters, Super Letters, Transparent Color Letters, Miniature Letters, Flashing Diamond Letters, Backlit Letters; Resin Letters, Flash Gold Letters; Neon Light Craft Stainless Steel Veneer Letters; Edge-wrapped Letters, Outlined Letters; Bulb Letters, Solid Letters, Honeycomb Letters, Borderless Letters, Irregular Letters, Straight Edge Letters.

More information Please Contact info@kilolaser.com ,or Online Whatsapp Contact:+86 18028969996

Send Email

Send Email