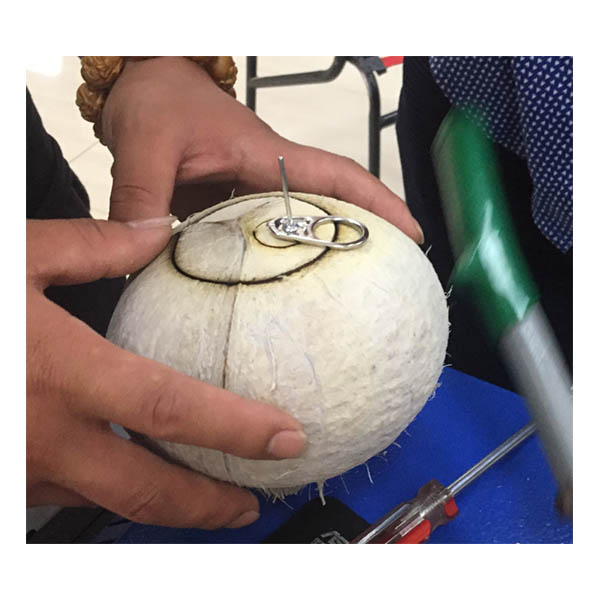

A different way to open the coconut laser cutting machine

A different way to open the coconut laser cutting machine

Coconut belongs to the genus Palmaceae, and it is a tropical woody oil crop and food energy crop. Its comprehensive utilization economic value is extremely high, so it enjoys the reputation of "treasure tree".

Coconut planting has a history of more than 2,000 years, mainly distributed in Hainan Province, with a small amount of planting in Guangdong, Guangxi, Yunnan and Taiwan. The current coconut planting area in my country is 4.6

10,000 hectares, with an annual output of about 243 million coconuts

Although the coconut production in my country has reached a certain scale, it still cannot meet the demand of the domestic market. Every year, a large amount of coconuts and coconut products are imported from abroad. therefore

It is necessary to strengthen the development of coconut processing mechanization, so as to ensure the sustainable development of coconut industrialization, promote agricultural efficiency, and increase farmers' income. Agricultural mechanization is the realization of my country's agriculture

The only way to modernization plays an important role in promoting agricultural economic growth and farmers' income

Agricultural mechanization is the only way for my country's agricultural modernization, and it plays an important role in promoting agricultural economic growth and farmers' income. Therefore, the coconut processing must be strengthened

The development of mechanization ensures the sustainable development of coconut industrialization, promotes agricultural efficiency, and increases farmers' income. my country’s coconut planting has a history of more than 2,000 years.

Although coconut production has reached a certain scale, it still cannot meet the domestic market demand. Every year, a large number of coconuts and coconut products are imported from abroad.

This article summarizes the working principles of a variety of coconut laser cutting machines, points out the problems of existing cutting machines, and puts forward effective suggestions for the research of some new coconut laser cutting machines.

Most domestic coconut products are processed by traditional manual or semi-manual methods, which have low processing efficiency and high overall costs. In foreign countries, coconuts are decoated, husked,

The I procedures such as peeling and cleaning are completed continuously by machinery, and the production efficiency is high; in China, most of the procedures are mainly completed manually, and the production efficiency is low, which also affects the cost of the product.

Sub-cutting is an extremely important step in coconut processing. After stripping, the coconut coat and coconut fruit (containing coconut water) need to be cut apart before they can be further processed into corresponding products.

At present, coconut cutting is mainly done by hand with simple machinery, mainly through the triangular teeth welded on the fixed tripod, using external force to pierce the coconut cloth and then hand I

Cutting. This cutting method is laborious, time-consuming, dangerous, and low in efficiency. Therefore, it is necessary to develop a mechanized coconut laser cutting machine to replace the traditional manual cutting.

Improve cutting efficiency and reduce risk

Introduction of laser cutting machine

The laser cutting machine is a professional laser cutting machine for roll materials, such as PU, artificial leather, genuine leather, clothing fabrics, shoes and other fabrics. The coconut laser cutting machine

The use of B-shaped/herringbone mesh belt, thickened steel pipe welding frame structure, realizes the function of fast and continuous curve cutting, and effectively improves the smooth operation and accuracy of the whole machine, and the cost is

Than higher. (Artificial leather cutting machine), suitable for cutting all kinds of clothing, bags, shoes and boots fabrics.

Coconut laser cutting machine knowledge

The laser cutting machine is the latest model developed for all non-metal cutting industries; the movement part adopts imported linear guides and high-speed stepping subdivision motors; embedded computer control

system. DSP digital high-speed processing technology, offline operation, humanized operation interface. The laser power and engraving cutting speed change freely control function, it is a non-metal laser cutting line

The best choice for industrial and laser processing centers is still a professional non-metallic laser for roll materials, such as PU, artificial leather, real leather, clothing fabrics, shoemaking and other fabrics.

Light cutting machine. The coconut laser cutting machine adopts B-shaped/herringbone mesh belt, thickened steel pipe welding frame structure frame, realizes fast continuous curve cutting function, and effectively improves

The whole machine runs smoothly and accurately.

Working principle of coconut laser cutting machine

Coconut laser cutting machine is to focus the laser light emitted from the laser into a high-power density laser beam through the optical path system. The laser beam irradiates the surface of the coconut to make the I part reach

The melting point or boiling point, and the high-pressure gas coaxial with the beam blows away the coconut shell or vaporized metal. As the relative position of the beam and the workpiece moves, the material is finally cut

Seam, so as to achieve the purpose of cutting.

Since its establishment, Jumao Laser has always been market-oriented, and has continued to innovate in laser applications such as laser cutting, engraving, and laser piercing. Kilolaser’s main products are coconut

Sub-laser cutting machine, panoramic camera positioning laser cutting machine, laser engraving machine, laser engraving machine, laser cutting machine, laser marking machine and other laser processing equipment; widely used in

Clothing, leather, advertising, craft gifts, plexiglass, electronics, electrical appliances, instruments, hardware, auto parts, apparel, wood industry, furniture manufacturing, model manufacturing, plastics,

Tobacco, packaging and printing and many other fields. For details, please consult Melody: +8618028969996

Enviar correo

Enviar correo