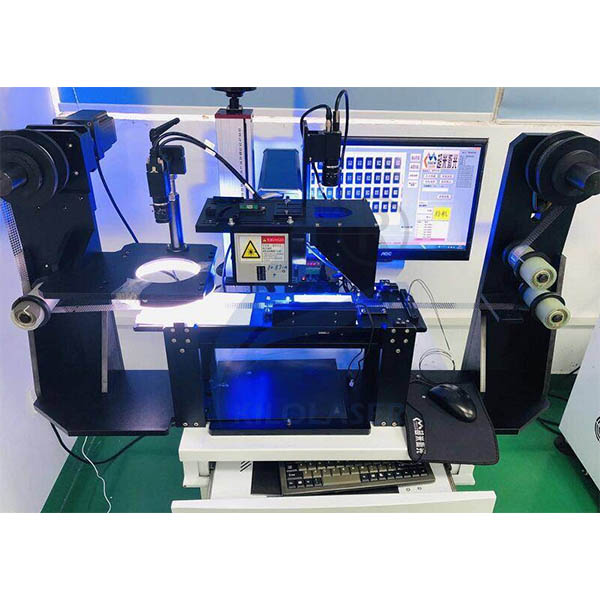

Camera CCD visual positioning laser marking machine customization

Visual laser laser engraving machine, camera CCD visual positioning laser marking machine system software customization

For general laser marking machines, during marking processing, the processed parts must be in a fixed position and must not be shaken during processing. The processed pattern can be processed to the designated position of the product. These are our common laser marking Common sense of standard machining process. Nowadays, new technologies continue to emerge. Chaomi Laser's newly developed visual positioning laser marking machine can realize accurate marking as long as the product is within the processing range of the laser marking scanning galvanometer; that is, even if the position is different each time , The processing position is also OK. This technology uses the principle of visual positioning.

First, the product is formulated and saved as a standard template. The product is photographed during processing, and the product is compared and positioned by the computer. After adjustment, the product can be accurately processed. The shape of the processed product can be recognized as round, square, and irregular shapes; this process is particularly suitable for small products, which can eliminate the processing of positioning trays and fixed fixtures, which greatly saves the laser marking processing cycle The integration of laser laser engraving machine marking machine and automation and industrial camera with CCD vision positioning system achieves high accuracy of product marking, minimizes the error deviation, and achieves some high-demand product requirements. Regarding the power of the laser engraving machine marking machine, we choose the appropriate laser power and the brand and characteristics of the laser according to the requirements of the customer’s product, which can save costs and improve the production efficiency and product quality as much as possible for customers. Stable performance, real consideration for customers, mutual benefit and win-win. Principle of CCD visual laser marking machine: This technology uses the principle of visual positioning. The product is first formulated and saved as a standard template. The product is photographed during processing, and the position is determined and positioned by computer comparison. After adjustment, the product can be processed precisely and accurately. The shape of the processed product can be recognized as round, square, and irregular shapes; this process is particularly suitable for small products, which can eliminate the processing of fixed and position trays and fixed fixtures, which greatly saves the laser marking processing cycle

CCD vision system can be equipped with: fiber laser marking machine, ultraviolet laser marking machine, CO2 laser marking machine equipment Kilolaser has a case of CCD visual on-line flying marking. There are many automation equipment companies in cooperation, assembly line, automation line, product workpiece conveying system and CCD visual control system, and the laser marking machine is connected according to the process sequence.

Enviar correo

Enviar correo